Model NO.: rubber molding parts Application: Home Use, Household Appliances, Car, Commodity, Electronic, Hardware Cavity: Multi-cavity Working Temperature: (-40℃-300℃) Mould Life: >1000000 times Customized: Customized Runner: Cold Injection Direction: Vertical or Horizontal Specification: CE, SGS, ROHS HS Code: 3926909090 Product Type: Household Electrical Appliances Manufacturing Processes: Pressing Forming Mould Surface Treatment: Polish Certification: CE, RoHs, SGS, UL, FDA, REACH Warranty: 5 Years Mold Materials: LSR Forming: Injection Trademark: Better Origin: Xiamen, China Auto Part Liquid Silicone Rubber Mold

Liquid silcone Rubber Mold Description

1. Liquid Silicone Rubber Mold Basic Properties

Two forming ways: Vertical and Horizontal

· Class 100,000 Clean Room

· Two-Shot

· Overmolding

1). Materials: LSR

2).

Other materials:Rubber, Silicone rubber, LSR, aluminum, etc.

3). Quality: RoHS and SGS standard

4). Feature: Non marking and Non flash

5). Size: According to your drawing

6). Color, Quantity, Unit price, Tooling cost, Tooling size: To be discussed

Materials | NR, NBR, SBR, CR, EPDM, TPR, TPU, Silicone, AEM, ACM, FVMQ/Fluorosilicone, FKM/VITON, FFKM HNBR, PU, Foam rubber, etc. |

Hardness |

10-60 shore A |

Mode of Production |

Compression, injection, injection transfer, extrusion, liquid silicone rubber |

Production Capabilities |

Machines(150T,200T,250T, 300T and 500T) |

Size/Color |

Custom |

Rubber Compound | UL, FDA, RoHs or REACH, approved |

Package |

plastic bag+ cartons |

Payment Terms |

L/C, T/T, Western Union, Paypal |

|

|

2. Liquid Silicone Rubber Mold Product Future

· Anti-Microbial

· Extreme Temperature Range

· Flexible

· Durable

· Superior Chemical Resistance

· Transparent

· Ease of Sterilization

· Superior Dielectric Insulation

1). Liquid Silicone Rubber Mold structure

Injection Mold, Plastic Mold, over-mold, 2k mold, Die-Casting Mold, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,etc.

2). Liquid Silicone Rubber Mold Base

HASCO standard, European standard, World standard

3). Liquid Silicone Rubber Mold Base Material

LKM, FUTA, HASCO, DME, etc. or as per customer's requirement.

4). Surface Finish: Texture (MT standard), high gloss polishing

5). Finish: Mirror finish etc.

6). Cavity / Core steel:

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc.

Cavity: Single cavity, Muti Cavity, based on customer's requirement.

7). Hot / Cold Runner:

HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brandetc.

8). Mould Life: 1,000 to 1,000,000 shots (according to your working environment)

9). Design & Program Softwares: CAD, CAM, CAE, Pro-E, Solid works, etc.

3. Liquid Silicone Rubber Advantages

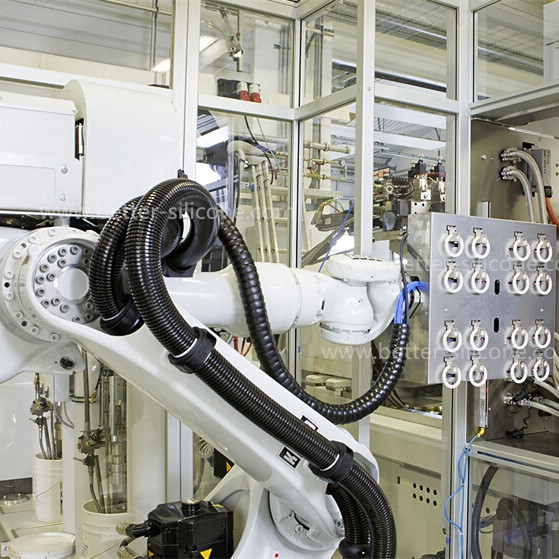

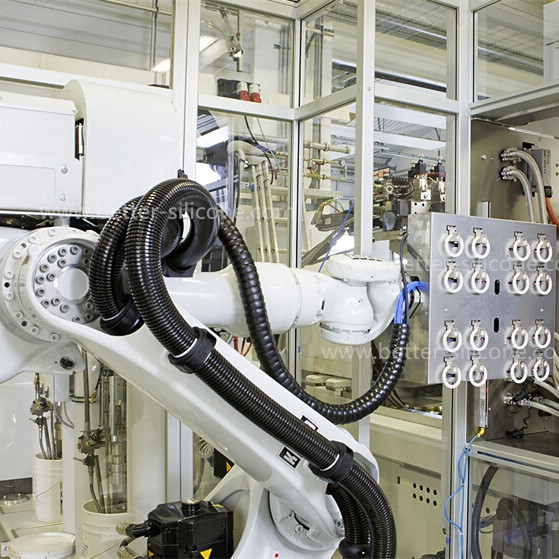

1). Liquid Silicone Rubber Equipments:

High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic

Injection Molding Machine for testing mold from 50-3000T available.

Package: Standard exported wooden box packed, fumigation process

(upon required)

2). Liquid Silicone Rubber Mold building lead time:

T1, 20~50 days, parts measurement report (if required).

Annual production: 250 sets of mold

4. Our Advantages

1). Five Plants:

Mold-Making, Silicone Rubber Compressive, Plastic Injection, LSR Injection,

and Assembly Plants.

2). Mold-Making Equipment:

CNC, Mirror EDM, EDM, Slowspeed Wire Cut M/C and other auxiliary equipment etc.

3). Production Equipment:

15 Sets Rubber Compressive Machines, 8 Sets Haitian Plastic Injection Machines, 2 Sets LSR Injection Machines.

4). Test Equipment:

3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5). Dust-free Environment:

LSR injection Machines, 3 Sets Rubber Compressive Machines, and Assembly Line in 100,000 rating Dust-free Plants.

6). Fast-reaction Organization:

Such as, One morning, Our Customer tell two precision rubber parts for smart cell phone need to revived, and ask we to send revived rubber samples to them at that day. At last, we made it at that day.

Contact us if you need more details on Silicone Molds. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Silicone Rubber Mold、Liquid

silicone mold. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Mold Tooling > Liquid Silicone Injection Molding

2. Liquid Silicone Rubber Mold Product Future

2. Liquid Silicone Rubber Mold Product Future